Our experts can help diagnose your issue

An artificial lift system should be chosen and designed during the initial planning phase of an oil field. However, in the haste to get a field on production, artificial lift may not be considered until after other production facilities are designed and installed. It is difficult to choose and install the optimum artificial lift system after the surface production decisions have been made. This is especially true in the case of gas lift.

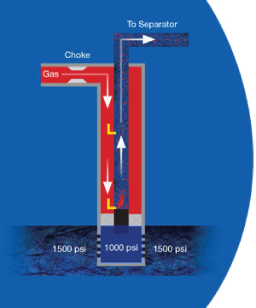

Continuous-flow installation designs vary depending on whether complete and precise well data are known. Reliable inflow well performance and an accurate multiphase-flow correlation are required to establish the approximate point of gas injection in deep wells. When the well data is limited or questionable, the exact point of gas injection cannot be calculated accurately in many wells. This being the case in today’s depletion drive and unconventional reservoirs, your Flowco specialist will design the gas lift solution to perform over the life of the system. When designing your casing, skimping on casing size can ultimately cost lost production that is many times greater than any savings from smaller pipe and hole size. The same is true in flowline size and length. In most cases, increasing the size of the flowline does not compensate for the backpressure generated by the added pipe length. Any item of production equipment that increases backpressure at the wellhead, whether it be wellhead chokes, small flowlines, excessive number of bends, undersized gathering manifolds and separators, or high compressor suction pressure, seriously impacts the operation of a gas lift system.