Accurate well site information delivered when you need it

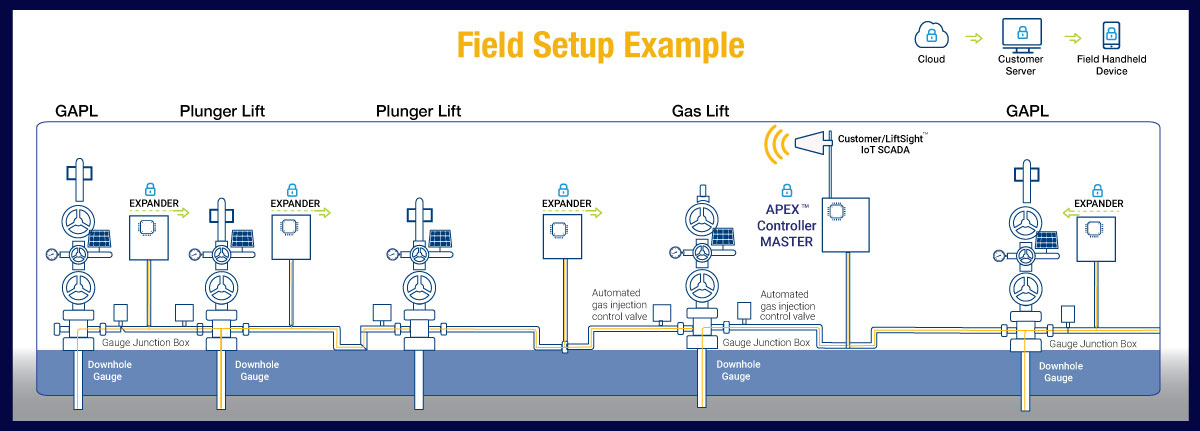

Introducing the APEX Multi-Well Controller, a more precise monitoring and control system for gas lift, plunger lift, gas-assisted plunger lift (GAPL) and hybrid-lift methods. Our new, single platform technology brings enhanced computing power, production possibilities and optimization capabilities to either an individual well or a pad of connected assets. The controller is a life-of-well-solution for the entire life cycle of the wells.

Works with your current equipment and SCADA system ... or ours!

Control up to 16 wells, each with unique configurations and settings.

Optimal control and production of the well can be automated and remote whether points are manually set and assigned by the operator or the assignments made by the AI algorithms in the controller. The operator has the flexibility to tune each artificial lift platform for peak performance. The system has the capability to optimize each well “regardless of lift platform” simultaneously. This system works seamlessly with most hardware and your existing SCADA systems or our LiftSight™ SCADA system, for new or legacy wells.

Applications:

The APEX Multi-Well Controller is a life-of-well solution. Although the system can replace existing hardware at any point, for ultimate well optimization benefits, it is recommended to install the system on new assets so the system can optimize/increase total production recovery and reduce required labor and downtime for each phase of the well’s life.

Specific game-changing gas lift-technology features include the ability to control the well on operator-specified rates and parameters, or the ability to optimize the well automatically. This technology, new to the industry, allows the operator to control gas-injection rates one of two ways: 1) critical velocity of produced gas, or 2) injection gas optimized based on drawdown of flowing bottom-hole pressure gathered from a live downhole gauge in production string.

In addition, optimization decisions can be made remotely without the need to be onsite to adjust parameters. This feature frees up precious time to help engineers and well service techs get more done in a day. To guide decisions through the AI-enabled solution, the controllers apply advanced gas lift optimization (AGLO) software.

For GAPL or PAGL wells, controllers employ a patented algorithm feature with cycle-skip technology, the first of its kind, and built to optimize both gas lift injection and plunger cycles to get the best performance out of independent plunger or gas systems, or both systems seamlessly combined.

“The algorithm’s results can be impressive”, says Dean Lehner, Director of Digital Solutions for Flowco. “While we cannot create production in reservoirs with little to give, we can deliver the available production at the optimum rate. The uplift varies”, he explains, “but for an operator who moves from manual production to automation, it’s realistic to see a 20% to 30% increase in production and a 20% decrease in injected gas volume.”

Digitalization is transforming oil and gas production and Flowco is on the leading edge of that change. The APEX Multi-Well Controller includes the ability to control up to 16 individual artificial lift wells from a single master controller. The data from these wells can be analyzed from the well local display, on SCADA, or on the Flowco app.

Features:

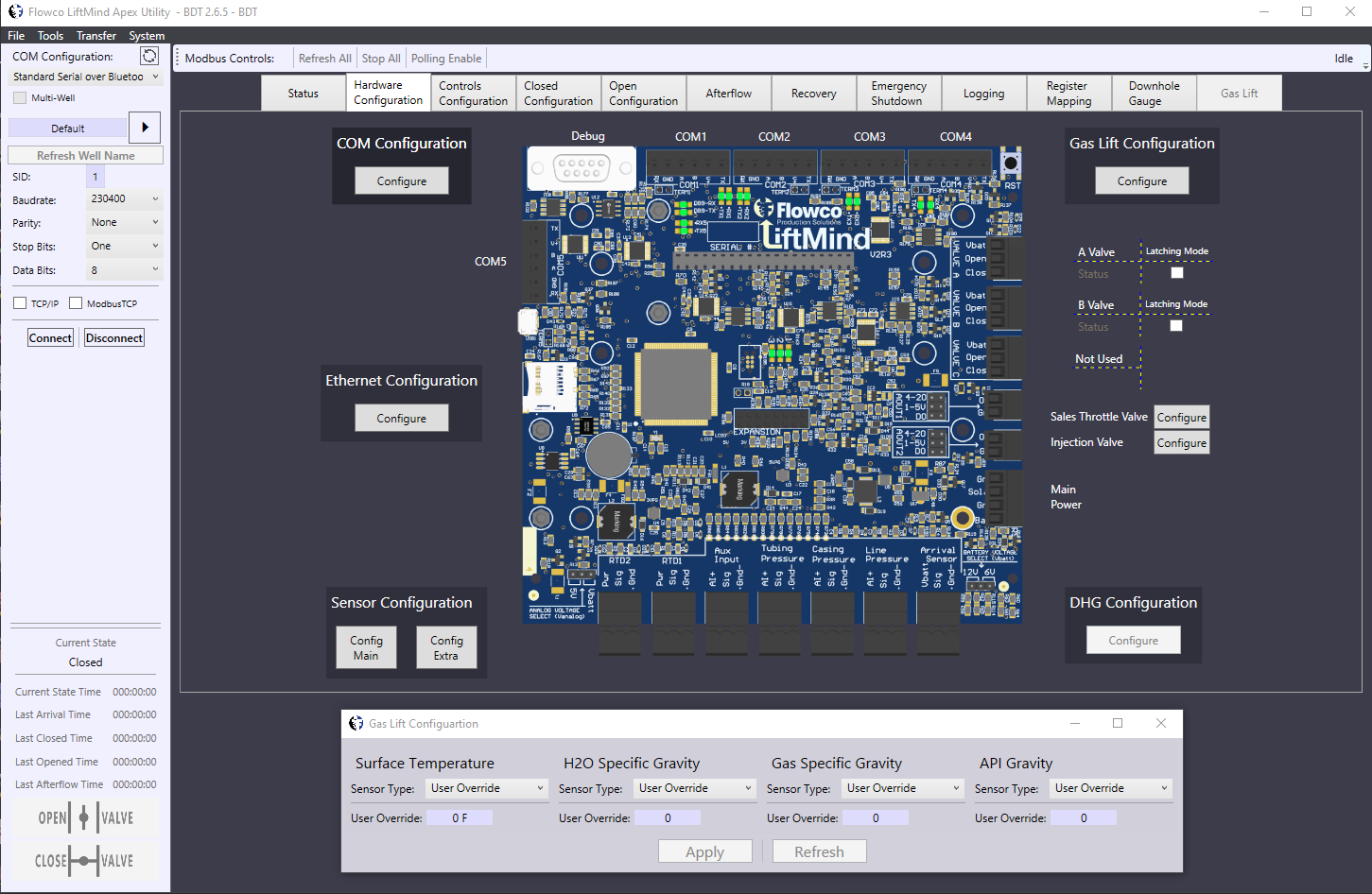

LiftLink software is an application software that runs on Windows® enabling rapid configuration, data retrieval, and firmware update capabilities.

The APEX Mobile Well Controller App:

The APEX App is available in the Apple App Store or Google Play Store. Easily configure the controller from your tablet or mobile device ... anytime, anywhere.