Aggressively reduce bottom-hole pressure

Overview

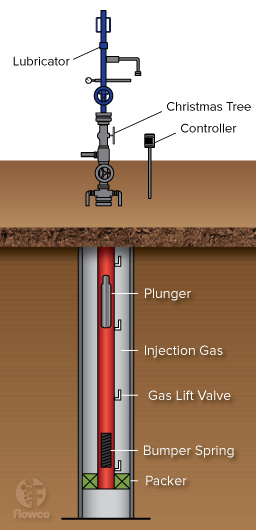

Plunger lift in conjunction with gas lift can improve efficiency in delifiquification of unconventional gas wells. When implemented, the dual artificial lift methods can more aggressively reduce bottom-hole pressure, and increase production in wells.

An intermittent gas lift system by itself can prove to produce less than desirable results in deeper wells, strictly due to the liquid fallback and the total liquid recovered per cycle. Liquid fallback in the tubing per cycle can be as much as 10% of the initial liquid slug per 1000’ of lift. With the addition of a conventional plunger, liquid fallback can be significantly reduced and more of the slug is delivered to the surface each cycle.