Built to Optimize ™

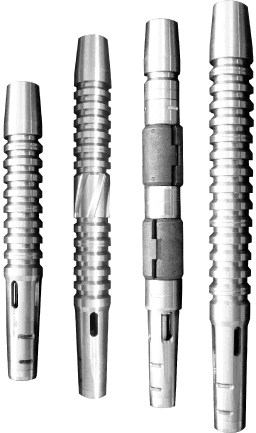

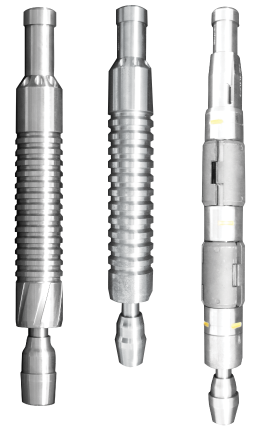

Continuous flow plungers, also known as bypass plungers, have a bypass valve that opens up the flow area through the center of the plunger that allows the flowing well to produce as the plunger is falling to the Bottom Hole Assembly (BHA). Once the plunger arrives at the BHA, either a dart valve closes or a ball is mated with a sleeve to create a positive seal or ascent position. The plunger cycles to the surface removing the liquids in the tubing string. This plunger method produces more cycles per day, delivering continuous fluid removal and optimizing high-rate wells to their maximum potential.