Helps protect against off-set frac interference

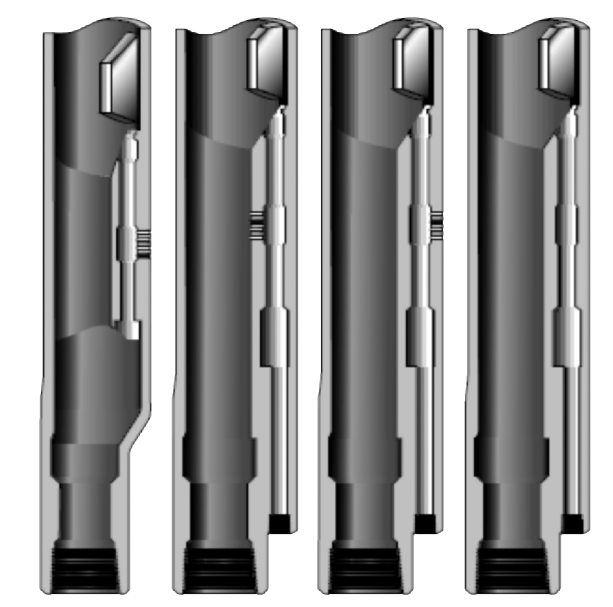

We also offer a full line of side-pocket mandrel for a variety of well completion applications. These high-quality tools have enhanced features to meet your most demanding production requirements. Each gas lift mandrel features a side pocket profile to receive gas lift valves, chemical injection valves, circulating valves, dummy valves, and dump kill valves. Several pocket porting configurations are available for applications such as water-flood injection, chamber lift, chemical injection, and annular flow.

For the complete list of available valves, dummy valves, circulating valves, latches and mandrels and the product specifics for each, we invite you to download the complete

Gas Lift Catalog or

Contact one of our experts for details on available and applicable products and solutions.