Reduce fluid density in your wells

A gas lift system normally requires valves placed in the production tubing string, which open at set pressures, injecting the gas that aerates the fluid in the production tubing. The hardware that connects the valve to the tubing is called a mandrel.

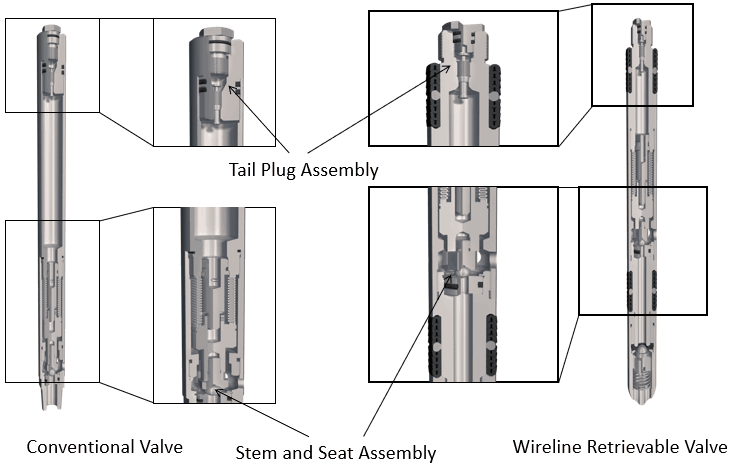

In the case of conventional valves, the valves are attached to the outside of tubing retrievable mandrels, which are then inserted into the tubing string at designed depths.

Wireline retrievable valves are installed into side-pocket mandrels by wireline units so that the production tubing does not have to be tripped to change valves.

The most common type of gas lift valve is the injection pressure operating (IPO) which consists of a nitrogen charged dome, bellows, stem and seat. When pressure outside of the bellows is greater than the dome pressure, the bellows contracts like an accordion, pulling the ball away from the seat and allowing injection gas to flow into the production tubing.

In the case of production pressure operated (PPO) valves, a high-quality Inconel spring replaces the nitrogen dome charge as the closing force. The common application for PPO valves are common-annulus dual installations. An added benefit of the Inconel spring is, the valve is not affected by temperature in the wellbore.

Proper injection gas pressure and volume managed at the surface allow the valves to operate as designed, for efficient maximum production.