Our experts can help diagnose your issue

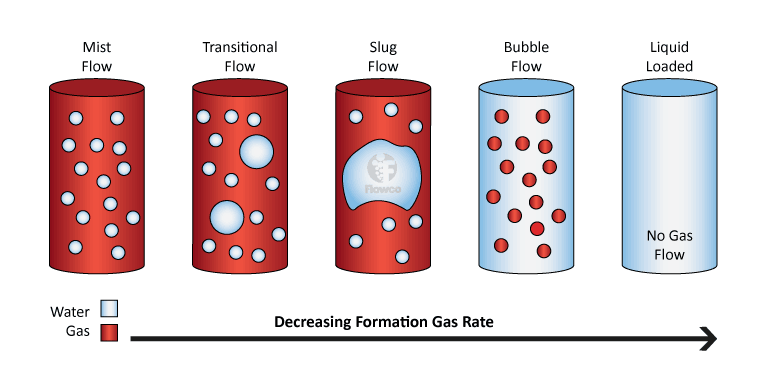

Liquid loading is the accumulation of liquids (water or condensate or both) in the wellbore, and can be addressed by several methods of artificial lift, including plunger lift, gas lift, and capillary injection systems. When the weight of a liquid droplet due to gravity overcomes the drag exerted by the rising gas in a column, liquid falls back and tends to accumulate at the bottom of the well. It occurs in vertical or deviated wells during production from natural gas reservoirs as a consequence of condensation and coalescence of liquids from gas streams.

This is common in both offshore and onshore production systems. Engineers are often tasked to identify and correct this type of production problem through operational changes (e.g. reducing wellhead pressure). Similarly, based on field experience, engineers can plan the well completion in advance and/or select tubing size to address expected liquid loading issues.

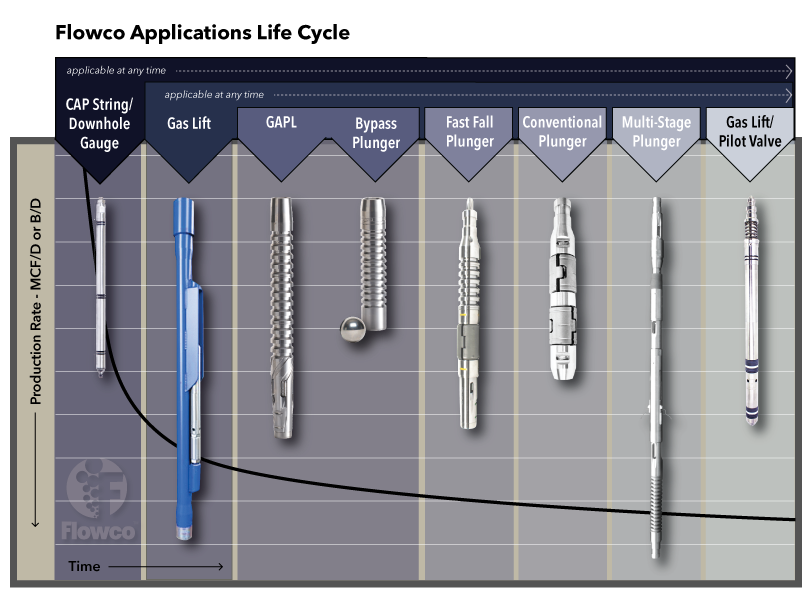

Several methods are available in aiding and managing production when severe liquid loading occurs.

Still experiencing issues or have questions? We can help. Our experts can work with your production team or create a custom well design. Contact us to coordinate with our local team and we will get back with you promptly.